Episodes

Thursday Jun 17, 2021

Episode 74 – Chemical Tricks, Outdoor Lumber, Frame & Panel Glue-up, & MUCH More!

Thursday Jun 17, 2021

Thursday Jun 17, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Second question: This question is for Sean, mostly. I'm getting ready to make a blanket chest with frame-and-panel front, sides, and back, out of cherry and walnut, but the recipient wants the wood from a single source. So for the first time I'll be making the internal panels out of resawn cherry rather than plywood. I remember that you said you had a problem with trapped hardwood panels in a set of end tables (I think?) you made for your parents a while back. I can't quite find the episode, but I was wondering what how you would go about doing hardwood panels for a frame-and-panel cabinet now -- what would you do differently to keep the wood movement under control? Any tips for making thinner, 1/2 inch panels in general? Thank you all -- I love supporting such a great conversation.

Adam

2) Hi guys! Another quick question - I'm making a small table and the base will be ash, ebonized with India ink. What would be a good choice for topcoat over the India ink? I was thinking of using a water-based poly, but it seems to "reactivate" the ink. Maybe shellac would be fine? Thanks!!

Dan

Huy

1)I was recently setting up to rip 60 facets to create a hexagonal column that is 1.5 inches across the flats. I have a right tilting arbor on my table saw. With my rip fence on the right side of the blade the blade tilts toward the fence. This would mean the top facet would be cut with that geometry and the the work piece would be pinched against the fence. I could move the fence to the other side which would allow me to cut the bottom facet and the work piece would not be pinched against the fence. I have never ripped on the left side of my blade. I ultimately decided to do this on the bandsaw which worked fine.

This brought up the question as to which is the preferred tilt direction for the table saw? Do we need one of each or is one direction more useful than the other. I would like to know your thoughts about this.

Thanks,

Dave Pollatta

Ontario, New York

2) I rarely hear mention of woods like Cumaru and Ipe for exterior use in articles, podcast or see it used by woodworkers I follow on social media, is there a reason? Weight and hardness Im sure factor into the decision as they can be difficult to work, but are they still worth a mention?

Guy

1) Question: I prefer 3/16” solid wood edge banding over the veneer, have to ask your opinion?

Harder to install, but better I think. Glenn

2) Hey guys! First off, I have to say, glad to have fellow metalheads in the woodworking community! I wanted to follow up on something good ole' Guy said a while back about how he makes his own Danish Oil.

Poly, BLO, and.... Naphtha? The Naphtha threw me for a loop seeing as how every YouTube video says to use Mineral Spirits. Well, I gave it a side-by-side test and yep, I liked Naphtha better! Good call!

So, my question is, what other chemical tricks do you guys have up your sleeve? Anything out of the ordinary novice woodworkers may not know? I pretty much have one of each and only a little used from each. So I'm looking for inspiration!

And lastly, we all hear the combustible chemicals need to be stored in a metal cabinet. Why? It'd have to cram in next to all my other wooden shop cabinets anyway.

Keep up the great work!

Paul

Thursday Jun 03, 2021

Episode 73 – Cabinet Door Panels, Switching to Metric, Glue Cleanup, & MUCH More!

Thursday Jun 03, 2021

Thursday Jun 03, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Shop router table or store bought. Pros and cons -trszki

2) Hi guys, I'm curious as to whether you guys use metric or imperial. I'm thinking it makes sense to switch to using metric for fine woodworking. I'm curious your take, what you are using and if you are using metric how was the switch and what are your pointers on making the switch. Thanks and I love the podcast.

Trent

Huy

1) I'm planning on replacing my melamine kitchen cabinet doors/drawer fronts with Shaker style I make. I'll be using Whiteside's Shaker Rail and Stile set in a router table and the doors/drawers will be painted.

I would like your opinion on material. I was thinking poplar for the rails and stiles and MDF for the panels.

Also, do you have a preference on type of hinges and brand? My current plan is to use European style, using jigs for drilling and mounting. I've never used European hinges, so any tips would be greatly appreciated if you agree this is the way to go.

2) Good morning fella's. I have a question about timing a unique finishing option when assembling an outdoor closet (used for storing shovels, rakes, etc.). I'm making the closet out of white oak and it will be hanging off of the back of my brick outdoor fireplace. Lately the internet cannot decide what to call the finish I want to use, so I'm just going to say that I want to do a burned/charred wood finish. The question is, when to do it. I want to do traditional mortise and tenon assembly where the bottom is mortised into the sides and the sides into the top. Do I burn all the wood first then cut the joinery? Do joinery first then burn while avoiding the joinery locations? Or assemble the whole thing and burn as one piece? Any help would be appreciated and keep up the great work.

Garrett

Guy

1)Hi there, I’ve written in before and appreciate you answering my questions.

I have another question that I would love some guidance on. I was wondering if your had any tips on cleaning up glue squeeze out on inside corners. The majority of my work I’m using titebond 2 glue. Ive tried letting the glue gum up and scrape it, and also tried wiping it right away w a wet cloth.

The orbital sander doesn’t full clean out the inside corners, and sanding the corners by hand and the rest of the piece w an orbital sander tends to show a subtle difference in how those areas take the finish. Any tips would be a huge help. Thanks again, Bryan

2) Thanks for the best woodworking podcast on the web! I know it’s best to joint and turn “downhill” in regards to grain direction. How does one tell which end of a board was closest to the top or bottom of the tree ?

Thanks again,

Tim in North Carolina

Thursday May 20, 2021

Thursday May 20, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Do you sand inside surfaces before or after gluing dovetailed parts together? Sanding before = potentially changing the fit and sanding after = having to sand inside corners. TheRoaringWoodwork

2) Do you buy your hide glue or make it yourself? Leather by Dragonfly

3) Would you guys ever want to build a wooden bathtub? Keith

Guy

1) So I’m new to veneering. I finally purchased a vacuum pump and bag. I love the fact that you can arrange veneer into different orientations to get the look that you desire. I want to make a modern credenza and want the grain to run in the same direction and match from the vertical carcass pieces to the horizontal carcass pieces. What’s the best method to ensure grain matches. Robert Couch

2) I recently got an old school desk and am planning to repair and refinish it so that my kids can use it. I'm starting to think about what kind of finish to use since it will obviously be getting some abuse, but I don't know a lot about finishes. I've just kept it simple and have always used Arm-R-Seal for my projects so far. I know finishes is a huge topic, but could you talk a bit about if certain kinds of finishes are better for pieces that you know will get abuse (e.g. desk, table) versus projects that are more accent pieces? Is it simply a matter of applying more coats to get a more durable finish or are certain types of finishes really better? Lastly, does the sheen (satin vs glossy) make a difference? Maybe nicks and dings wouldn't show as much with a satin sheen? Thanks in advance and keep up the great work. -Billy

Huy

1) After reading Bill Pentz’s website, my eyes have been opened as to the proper way of setting up a dust collection system. I’d like to run a 6” main run coming directly from my Oneida dust collector inlet. Pentz’s suggests maintaining the duct sizing and reducing right up until the tool. He also suggests keeping the ports as large as possible as well. However, almost all of my tools have a 4” port. For the bandsaw, it makes sense to have 4” ports since there are two of them (one right under the lower roller bearing and one in the lower cabinet). However, my table saw only has one 4” port. Wouldn’t it be better to increase the port size to 6” to get more airflow? Do you think it would be worth increasing the port size to 6”? For context, I have a SawStop 1.5hp PCS. Moser Woodcraft

2) I’m very new to woodworking. I have a modern chair piece that I’d like to build with lots of angles. I have it modelled out in SketchUp and everything looks great. However, when I start cutting the test pieces on the miter saw or on the table saw with a miter gauge, I can’t get the angles just right and I end up with small gaps. Everything will be joined with floating tenons. Are there any techniques or methods that might solve my gappy joint problem? All.Woodworking

Thursday May 06, 2021

Thursday May 06, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Great show guys. Been listening a while and I've heard them all. Thanks for sharing your experience. Hoping you can give me some ideas for potential workaround. I recently made a mitered box out of a nice piece of cherry, with continuous grain running around the sides. I rabbeted the inside edges of the top and the bottom and used those rabbets to seat in some 1/4 in. baltic birch plywood veneered with bubinga and wenge. I'm a relatively new woodworker but I think they turned out pretty nice. After the glue dried I noticed that I had slightly undersized one of the rebated panels on two of the ends. Maybe somewhere between a 32nd and a 64th. As this is on the outward face of the box, what are the alternatives for closing this gap? The rest of the box looks pretty nice, and I'm afraid to goof it up with a sloppy patch job. Any suggestions? Thanks again guys for the great work! - John

2)So I've been trying my hand at shellac, with mixed results. I've put a coat on some soft maple sanded to 220. I decided I didn't like it so I wanted to sand it off. After waiting several hours, while it looks dry and feels dry to the touch, when I sand it, it is clogging my sandpaper. I then tried waiting over night. Same results. Is this normal? Some details: it is a 2# cut of amber shellac flakes, freshly mixed with denatured alcohol, applied with a blue shop towel. Temps were in the low 60's to high 50's with humidity ~40-50%. Shellac flakes don't get old do they? Is it possible that the denatured alcohol doesn't have a high enough % of booze in it? I did buy it @ the big box store. -Mark

Huy

1) How would you get rid of bandsaw marks from thin shop made veneers, that are less that an eighth of an inch thick, but still come out with a consistent thickness. I don't have a drum sander, yet. Was thinking of a sled with the veneer stuck down with double sided tape in the planer. Just afraid it will explode under the planer knives. I've tried a hand plane, to no avail. I have an old Inca, Jointer/Planer with a Tersa head. Any help would be very cool.

ps..Love the Podcast - Ken

2) Hey guys. I’m looking into buying a track saw along with corresponding work table. More specifically, the . I’m hoping you all could give some insight when comparing and contrasting these two and whether the Kreg system, while more budget friendly, sacrifices quality or is lacking in any way. Love the show and look forward to hearing your thoughts. Thanks, Phil.

Guy

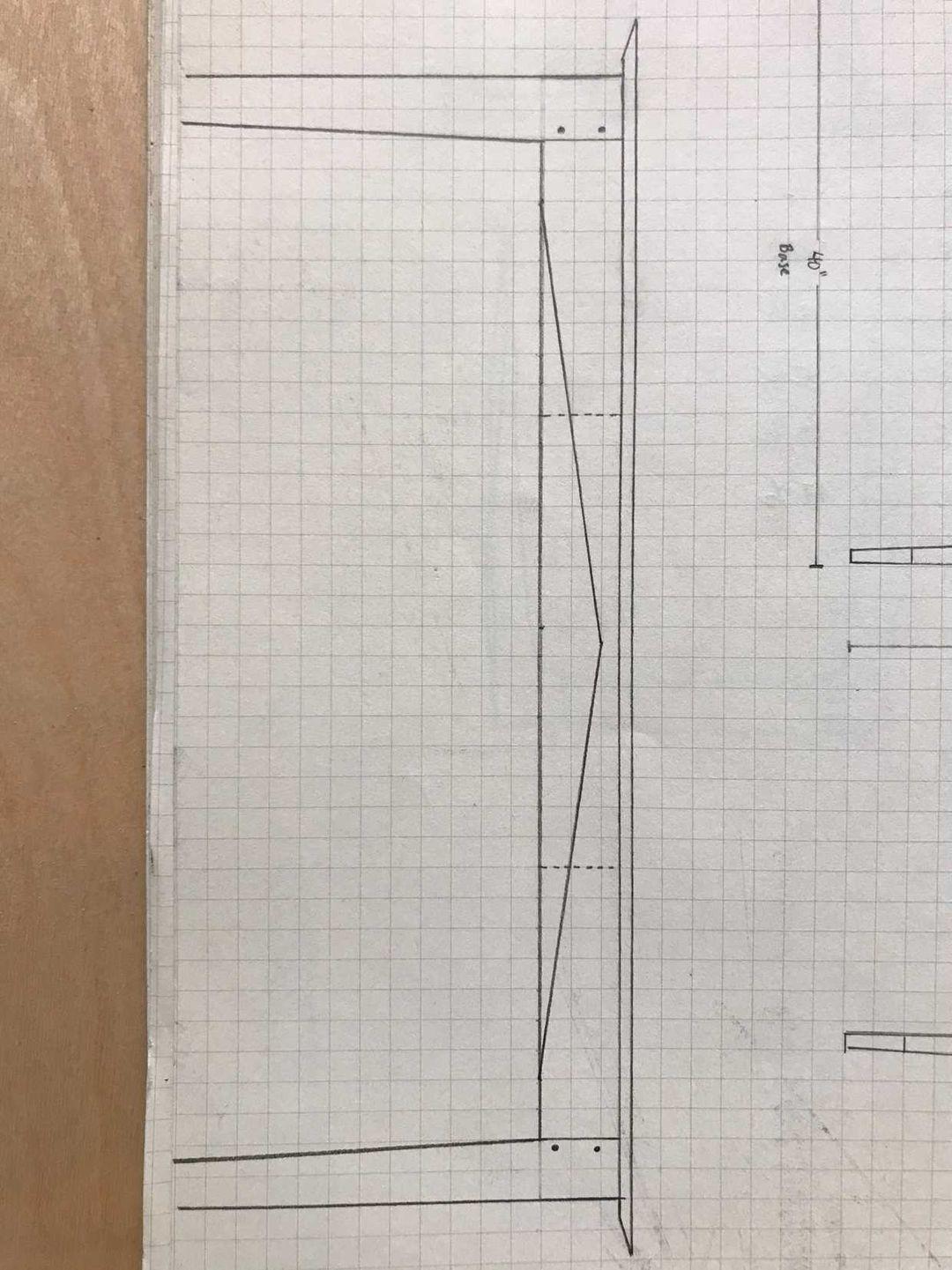

1) I have many slabs of 8/4 maple that have been air drying for a couple of years after I milled them. I know how you feel about slabs, but don't worry, I plan to dimension these to 6/4 and 10" wide with the aim to build a dining room table of approximately 8ft long by 40" wide.

For legs, I'm thinking of the "panel" style that are situated about a quarter of the way in from each end. I'll use a cross beam between the two panel legs, but does the top panel require an apron or any additional underpinning or support structure?

Thanks for near 70 shows of insights. Glen

2)Hey guys - can you explain why tool companies produce / sell multiple tool brands? The latest I’ve noticed is the South Bend tool line that Grizzly is distributing - it looks very similar to the Grizzly line of tools but with a new paint job. I’m sure they’re not the only company with this practice. What gives? As a follow up, as someone only a few years into the hobby, which single brand would each of you select if you were starting a new shop (and I’m assuming Guy’s answer will be Powematic)? Thanks for the episodes - really enjoy them - Mike

Thursday Apr 22, 2021

Episode 70 – 36" or 52" Table Saw?, Sander Vibration, Wax Removal, & MUCH More!

Thursday Apr 22, 2021

Thursday Apr 22, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Hi all, greetings from Australia. Love the show and appreciate your willingness to share your knowledge with people like me who are just starting out. I have a question about router dust collection. I have recently built a router table and am looking at the dust collection. I have a router lift and round body router installed I am waiting for the port to come for the fence dust collection, but have a question for under table dust collection. What do you recommend here? I have seen something from milescraft called a dust router 1501 that has a router fence and router dust collection. Currently the router is mounted on a router lift which technically will sit inside a space covered by a door. Any advice welcome - Jamie

2) I just bought a new house with some property and it has

A big detached 2 car garage that will be my new shop. I was planning to get a Laguna Fusion F2 to upgrade my dewalt jobsite tablesaw, but they are backordered until August. I can still find Sawstops in my area so it looks like I'll plop the extra money and save my life. At this point the 52 inch fence is only $100 more than the 36 inch

In your opinion is the 52 worth the money and extra space or is the 36 big enough, I mostly build custom furniture but will be doing all the cabinets in the new house remodel, bathrooms and kitchen as well as bed frames, a master closet, building etc. So a mix of sheet goods and hardwood builds.

I don't have a track saw, I use a circular saw with the bora NGX strait edge system to roughly break sheet goods now.

Thanks for the great show I learn so much.

Will @ Oleksy wood works

Guy

1)I have a question about Festool sanders. I currently use a delwalt 5" random orbit sander that works well enough. I have it hooked up to a shop vac that I run with a standard filter and a hepa filter at the same time. This results in no dust coming out of the vacuum, and it gets most of the dust from sanding coming off the sander itself. I still have to wipe down my work after sanding which I don't mind.

I recently built a desk and had to sand vertical surfaces for the first time and was surprised at how much harder this was and how numb my hand was afterwards. It was pretty miserable.

I have the chance to upgrade to a Festool sander and I see several different used models for sale locally. I was leaning towards the RO 125 because of its versatility but have read that it can be difficult to handle and can vibrate more in random orbit mode than the sanders specifically designed for random orbit sanding like the ETS.

Will one of the Festool sanders actually leave a better finish than my dewalt? If so, is it better to go with the RO 125 because of its versatility or will a dedicated random orbit sander have less vibration? Will I see a difference in finish between the RO 125 and an ETS 125?

I am somewhat new to woodworking but I am fortunate enough to have a well outfitted shop. I have been working on smaller projects like boxes and shoe racks. I'd like to get into building more desks, tables, cabinets, and doors. I don't really strip or refinish furniture, so I may not have a need for the material removal capabilities of the RO 125? Thanks Julio

2) Hello, I've been a fan of the podcast since the beginning and thought I'd finally submit a question. So, I plan to make one of those bath tub trays for my soon to be wife. It will be made with 1 inch thick purple heart wood with various little slots and grooves and routed out sections to place a wine glass, hold a phone or book, put a candle on that sort of thing. My question is what would the best finish be for something like this that is always going to be used on a bathtub and be exposed to water every time it's used even if it's only for short periods of time. I've basically only ever used typical stain and brush on poly/varnish for my projects, but wouldn't mind using a satin oil finish for the look. What do you guys think is the best finish for such a thing? Thanks - Brendon

Huy

1) Jonas from Germany here! Love the podcast and the wealth of Know-how you guys provide!

Since you’ve been asking for questions, here is mine:

I’ve been trying to wrap my head around wood movement in general and more specifically around keeping wood straight while still allowing for movement. I am in the midst of building my workbench right now and a couple of questions have come up. I know that wood moves mainly across its width. Is that still the case if you flip a bunch of boards 90 degrees and glue their face sides together, as is often done for workbench tops? Not sure if that would mean that the top now moves mainly in its thickness or width.

Also, If i wanted to build my workbench more like a mft (but from solid wood) with aprons on all sides and less like a traditional workbench. What would I have to look out for regarding grain direction and wood movement? I guess the long sides/aprons are not the problem as they Would be Long grain, just like the top. What about the short aprons?

2) Hello Guy, Huy and Sean. Over the summer I made one the nesting serving trays from a plan in Fine Woodworking. I used paste wax as my finish. It looked great and really brought out the character in the mahogany. Then I used it for it’s intended purpose on a camping trip. It was much more convenient than bringing the cooking ingredients from the camper to the grill, then I put the plates with the warm food on it to bring to the table. The heat melted the wax. Did I just ruin my piece by using wax as the only finish? Is there a way to remove it and put something more durable on like lacquer or shellac? Is there any finish that I could put over the wax if I fix the affected areas? If I have to remake it, I have enough mahogany left over, but I’m cheap and I ran out of waxed cotton threads for the handles... help me Wood shop life, you’re my only hope!! -Joshua

Thursday Apr 08, 2021

Episode 69 – Dream Bandsaw?, Three Phase, Tunes in The Shop, & MUCH More!

Thursday Apr 08, 2021

Thursday Apr 08, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Hey guys, I became a patron supporter a couple months ago and I really love the format of the podcast. I am a beginner woodworker who is in the process of acquiring more tools. I would like to start to resaw my own lumber from rough sawn. I was hoping to get your advice on what is the best bandsaw you all would recommend. If money was no object what would you recommend? Again, my main objective is to resawn Lumber and the number one challenge I’m facing in picking a machine is they are not on display at any of the usual stores, Woodcraft or Rockler. I appreciate your response in advance. Juan from Boston

2) Hey guys! Digging the podcast, keep up the good work.

I have a question and curious how you guys would approach fixing tear out on a table top?

I’ve got a ambrosia maple top I just glued up. And noticed a nice 1/2” x 1/2” wide chunk that’s about a 1/16 to 1/8” deep right in the middle of the top. How would you fix it? Also you can’t flip the top, there another mark/divot that’s worse on the bottom side.

Would you use a decorative inlay/ bow tie? Or try to hide it?

Details: Top is 1.75” thick, I know a little heavy but gets a large chamfer on the underside. Overall it will be 40” wide by 7ft long.

And I don’t have access to a wide belt sander.

Thanks, Jesse

Huy

1) Hey guys! Great show! I have been having problems with raising and lowering the height of my table saw blade. I have a Grizzly 1023RLW. It is new from Grizzly, and have had it for about 6 months. My question is, what do you guys use as a lubricant for the moving parts? I cleaned everything good, and used grease. Like packing bearings grease. It works great for about a week, and then gets all packed with sawdust. Is there a better way? Thanks for the show, it has been a real help. Keep it up! Marc

2) Good day Sean, Huy and Guy. Thank you for the podcast. It is an excellent resource. I prefer the french pronunciation of Guy, so in my world Huy and Guy rhyme which greatly increases my enjoyment of the podcast.

I recently got a 20" bandsaw for free. It has a 3 phase motor right now. Is there a compelling reason to purchase a phase convertor as opposed to a new motor? They are in the same ballpark in terms of price--the motor being a bit more expensive. It may be more difficult to find the motor with the proper mounting brackets and etc. but I would guess I can find it. Is there a performance based reason to select one or the other? (Huy should great insight on this as a rocket scientist which is a close cousin to an electrical engineer, right?)

Thank you for any insight you may have. Darrick

Guy

1) So a bit of non woodworking question for you - I need some new music to listen to in the shop. What’s on your playlists right now?

For the record, I don’t listen to music while I’m using anything with a blade or cutter, it’s too distracting. only when I’m sanding and finishing. Just sayin’.

Thanks, Mark B

2) My shop is being constructed and I’m about to face the electrical decisions. One decision I’m stuck on and could use some other input on is about the tools in the middle of the shop. I don’t like cords running across the floor to trip on, so I’m considering putting some outlets in the ceiling and having the cords come down with the dust collection run. I’ll need 240 and 120 for the center tools. Does this sound like a good idea? Should I try to get something in floor instead? This would add cost, but then think I would need to consider adding dust collection pipe as well to free up my head space. My ceilings will be vaulted, so that brings another complication. Just looking for thoughts from seasoned woodworkers.

Brian

Thursday Mar 25, 2021

Thursday Mar 25, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Guy

1) Hey guys! I love the pod cast, ya'll really do a great job. My question is about radial arm saws. I have recently started selling tables on the side to try and make some extra cash. Right now I do pretty much all my cross cuts with my 10" Chicago Electric miter saw and I am tired of having to flip over anything wider then a 2×4 to cross cut. It seams that these radial arm saws are a dime a dozen on the market place apps and can be bought pretty cheap. How do they stack up to a sliding miter saw? I've really been thinking about giving one a shot just based on the $75 price tag. - Jimmy

2) Another question for you all. Every power tool I own seems to come with it's own set of tools - allen wrenches, different heads, attachments, maybe a spare cutter or bolt, etc. How do you organize these 'spare parts' in your shops to keep them handy when you need them, and help identify which of these things belong to which tools? Attach them to the tool somehow (with string? duct tape? magnets?) With hand power tools, keep the paraphernalia with the tool?

The Ziploc bag method I'm using now seems so gauche. thanks for the great show Mark mlbettwoodworks

Sean

1)In a recent episode you discussed laminating two pieces of hardwood together and the need to offset grain directions to avoid warping. I’m building a simple, traditional writing desk (with a modern flare) and my plan is to accent the air dried walnut drawer fronts (5/8” thick) with an 1/8” piece of curly maple. I’ll be routing out the section to receive the maple taking the walnut thickness to about 3/8”. My plan at that point was to laminate the maple into place.

Is this a situation where I should be concerned about movement? Do you think the lack of material thickness will minimize these potential issues? Any advice or input would be helpful. I have sent a sketch photo to your IG page for reference. Cheers, Taylor (not Tyler)

2) I recently completed a build for two white oak desktops and, in my excitement to see how the grain would pop and without considering the ramifications of my actions, I threw on some mineral oil. Man, those desktops looked BEAUTIFUL. After applying just one coat, I realized I should've done some research. I'm still learning about finishing techniques and figured I could use mineral oil the same way as mineral spirits in this context. I quickly realized the gigantic mistake I had made. After spending some time on a few woodworking forums, it became clear that there's really nothing to do but lean into finishing these desktops with more coats of oil as no other finishes will properly adhere. However, I have seen some comments mentioning shellac as a possible option since shellac and mineral oil are used in combination for French polishing. This is not necessarily the look I'm going for but I'm wondering what you'd advise in this situation.

PS I'd really like to avoid sanding it all down again. And its 10 degrees outside so I'm limited in chemical options if I have to open the garage doors for ventilation.

Thank you guys for all you do. This podcast is always a huge help!

Christina

Huy

1)I currently have my bandsaw (Rikon 10-326) set up for resaw with a 1/2" Woodslicer blade and its working great, but now I need to cut some curved workpieces. I only need to do a couple and then I would want to go back to the setup for resaw.

I dread having to change the blade and set the guides for 1 cut, and then again for resaw, but I also don't want to distort or dull my resaw blade.

Should I just use this blade for both jobs or is there a blade or configuration that works for general purpose to minimize the changing blades and guide setup? Dan

2) I have a question regarding drawer slides: I am just getting into cabinet making and am excited to slowly make cabinets for my shop. I am first working on a built-in of sorts in my house as part of a bathroom remodel. The built in faces out into the hallway and the back juts into the bathroom, it creates a nook for the toilet area. I made the carcass and have it installed in the wall so that the bathroom side of the project can continue.

I plan to have two deep drawers on the bottom and then shelves with drawers above. I am a little unsure of how to properly size the drawer slides and would love to hear a discussion from you three on this subject. I ordered 21" undermount Blum softclose slides last fall when I was planning the project. Now that the carcass is made, the inside depth from front (frameless design) to back is 20 3/4". I see quite a bit online regarding how to install various drawer slides including different YouTube videos that you guys have but I am having trouble with the beginner step of learning how to size the drawer box and drawer slide properly. Do I buy a slide for the cabinet depth or for what my drawer box will be? I think the next available size down for a Blum slide is 18", will this be difficult to mount in my deeper carcass? Thanks guys, keep up the great content! Jeremy

Thursday Mar 11, 2021

Thursday Mar 11, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1)Hey fellas. 2 questions for you

- Purely hypothetical- you can only have 1: table saw or track saw. And why?

- When sanding back, how far is back? Are you aiming for a perfectly flat surface? This is harder to achieve on open grain woods like oak, yes?

Keep up the great show. Mark Aka Matt

2)I am finishing a large table, 10'x 5', and would like to use Shellac on it, then seal it with water based poly, specifically General Finishes High Performance Water based Satin.

- How important is it to keep a wet edge with the shellac? Since it dries so quickly, I can see some difficulty keeping a wet edge on a piece this big. If so, any advice on how to do that?

- On a test piece I've been using, the above mentioned poly is drying FAST. As in completely tack free in under 10 minutes. I'm working indoors in Central Ohio, with temp about 68, and low relative humidity, probably around 35-40%. Should I be concerned that the Poly is drying that fast? Will it cause any problems?

Thanks and keep up with the great show!

MLBett WoodWorks

Huy

1) Good morning. I have a quick question about building a slab top hand tool bench. I was recently gifted a great 60”x20”x4.5” oak slab. I’ve read Chris’s book and would like to do a roubo style bench. My problem is my current shop is in the basement and I would eventually like to move to a new outbuilding shop down the road. What design ideas would you suggest for a sturdy base design that is functional but could eventually be broke down and moved them out back together? I was thinking sliding dovetails in the bottom of the slab then build a base to connect to that? I have no idea. 😂 appreciate the help. Cheers, Garrett

2)New Patreon supporter here. Love the show. Love you Huy! Love you Sean! Kind of like you, Guy! HA! (Why is he so cranky?!)

I'm a garage hobbyist who loves to work in the shop as a getaway from real life. Generally speaking I'm a neat freak and the dust in my garage makes me crazy. I'm currently using a 2HP Harbor Freight Dust Collector with Dust Deputy XL and Wynn filter. I've got a combination of PVC piping and flex hose to my tools. The PVC joints are taped together but not glued. I try to keep the wynn filter blown out and have even taped the top of my plastic bag to the metal housing for a better seal. Every time I turn the collector on I get a ton of fine dust in the air. It covers everything in the shop and even gets to the point of looking a little foggy. I intend to get an air cleaner (or just some box fans) but I can't imagine that it will take care of all the dust. I don't know what to do. I'm considering the Oneida Supercell because it seems totally self contained with no exposed filter or bag, but that's a big purchase for a hobbyist. I see shops that look spotless online. Is having a dustless shop really possible? Is there anything you suggest I look at in my current system to minimize the dust?

Thanks for all you do for the woodworking community and Guy, please cheer up. Thanks- Ben in North Carolina

Guy

1)Good day gentlemen. Great information but let's jump right in and not boost your egos more than necessary :)

My wife and I built a custom house in 2020 which somehow has a master closet that is only 50sqft smaller than my woodshop. Can you help me understand how I allowed this to happen?

Ok kidding, I am grateful to have my own shop space but I would like your thoughts on using pre-finished plywood for making built-ins for said closet. It will be a huge project and the thought of spraying latex or a pre-cat lacquer on that many cabinets sounds daunting.

The built-ins will be some shade of white with lower drawer banks and upper open shelving/hanging areas. On the lower sections, I can use UV finished ply as the interior will not need to be white but can I get custom colors for the open uppers?

If I go the route of using pre-finished ply then all joinery will need to be concealed and I would likely need to purchase a system for this. The Lamello p-system looks slick but a hefty investment. What system would you choose for this application? Thank you for your input, Chris Olsen

2) Hey fellas, when starting a clamp collection, what size parallel and f style clamps do you use the most? My future projects include several cabinets for a wet bar, benches, coffee table, and maybe a round dining room table. Thanks for the help! - Chris

Thursday Feb 25, 2021

Thursday Feb 25, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Hey fellas. So I’m having some trouble getting nice glue lines when I’m edge jointing long boards (6’+). I’m building a table top (72”x36”) out of hard maple. How particular are each of you when building table tops? Should the glue joints be flush off the jointer? Do you massage them with a hand plane? Are small gaps ok as long as they close up with a bit of clamping pressure?

I have checked, rechecked and rerechecked my jointer and it seems dialed in so I’m pretty sure this is user error.

Thoughts on using a magnetic feather board on the infeed side of the jointer to help with stability?

Love the show - keep it coming!

Mark

MLBettWoodWorks

2) Hey guys I have a question/conversation. Just wanted to get your guys thoughts on the topic of the expense of woodworking as a hobby. I feel a lot of woodworking influencers I guess you’d call them are afraid to actually talk about the real cost of woodworking. I feel it’s taboo or something. If your someone who is cheap or doesn’t have the means I don’t think this is the hobby for you. Things like having a climate controlled shop. Having proper dust collection. Having all the proper 220 installed in your shop. Then having the right tools to do each operation. I dunno I guess I’m just blunt about it. If you wanna do this hobby right and also safely it’s a lot of money. Just wondering your thoughts

Nathaniel

Guy

1) Thanks for the best woodworking podcast around! It's so good to have a podcast that's all relevant information and without the hosts' constant snickering among themselves, as if they think that's entertaining. Here's a question regarding pocket hole joinery:

When assembling cabinets for my shop, and other projects using pocket screws, I often end up with the parts sliding out of alignment as the screws are installed. I have and use the Kreg clamp that has the pin that goes in one of the pocket screw holes, but still often end up with the parts slightly misaligned. I'm considering driving a couple pin nails before driving the screws. Any other ideas that won't leave telltale (albeit small) holes that have to be dealt with?

Thanks again for the great format! Tim

2) Hey guys,

I’ve been pondering the idea of adding a second smaller dust collector to my shop instead of upgrading to a 3 hp system fully piped to each machine.

Currently I’m in a small basement shop that’s about 400 square foot. I have a HF dust collector with a cyclone and filter. I’ve piped it with 4” to the table saw, jointer, planer and miter saw. It’s not the best but it gets most of the chips from the planner and struggles with the other machines.

My thought was to add a wall mounted dust collector to the table saw and the miter saw. Then leave the planer and jointer hooked up to the cycle dust collector.

Curious how much of a difference a larger dust collector fully piped would make.

Thanks,

Jesse

Huy

1) Hey Guys...Wondering if you could give us opinion of the Festool domino machine. Any tips and tricks you may have figured out? Can the cutters be resharpened? What size domino do you mainly use? Do you make your own dominoes vs. buying them? Just curious. - Dale

2) Hello gentlemen. First, thanks for your input w/r/t my belt sander question. I did keep it, and it saved me a bunch of elbow grease on an epoxy project.

I’m kicking around the idea of installing a wood floor in my shop which is a 2 car garage with a concrete floor. I would frame it with 2x4 with plywood on top of those right over the concrete. Benefits include :

- easier on my feet

- save the edges of my dropped tools

- be able to run electric & dust collection, among others. I can’t seem to find any drawbacks outside of the cost. What am I missing? For the record no cars park inside, and I do have large stationary tools including a table saw, 6” jointer, bandsaw etc.

weight considerations? Should I use 2x6 instead? What about moisture possibly wicking up through the concrete?

Thanks for the input and the great podcast.

Mark Bett

Thursday Feb 11, 2021

Thursday Feb 11, 2021

Support us on Patreon: https://www.patreon.com/woodshoplife

Sean

1) Hey guys - Ray here from Ravenwood. I love the podcast and the information it provides!

I’m building a hand tool cabinet and had a quick question about storing hand planes in a plane till. I know conventional wisdom is to store planes on their side to protect the plane iron? How does a plane till change this? Do you guys retract the blade when storing in a till, or is the idea that the angle of the till sufficiently mitigates gravity such that the plane can remain set up?

2) A woodworking podcast that actually has woodworking content! Love your show.

My question deals with routing dados on large carcass builds by hand.

When placing a straight edge, sometimes the router wants to jump on me and go off line. I tried placing a straight edge on bottom and then at the top of router while going in a left to right direction.

Should I be using two straight edges to keep router from veering of line? Or are there other factors such as speed and depth of bit?

Thanks. barriowoodworks

Guy

1) Hey guys, first love the podcast! Of course I've learned that I cannot do anything else while listening as I'm constantly having to pause the podcast and write stuff down haha.

My question is about shake/rail and stile doors and drawer fronts. I've made a handful at this point and it seems no matter what I do they never end up flat. They are twisted or just bowed out a bit or something. I try to be as careful as possible during glue up etc, but they just never end perfectly up flat in the end. Is there a good strategy that I just don't know about? I use poplar usually for the rail/stiles and plywood for the inserts - Ephraim

2) I'm new to the world of veneering and would like your advice for my current project.

I'm building a simple hand tool cabinet from rift sawn sapele and would like to accent the door panel and drawer fronts with a contrasting veneer. Most likely, it will be maple.

In my design, there are two banks of drawers. The dimensions of their faces are 3.5" x 6" for the top set, and 4" x 9" for the bottom. Ideally, they will be 5/8" thick.

My plan is to use baltic birch as the substrate for the door panel, but I would like to use solid wood for the drawers.

Given their size, how important is it to have a balancing veneer? If it's not important, should I consider a more stable cut of wood, such as quarter sawn or rift?

Thanks in advance, Justin

Huy

1) Picture an oval shape in 2 halves and each edge will have fingers to interlock a center divider which will utilized a divider; shelf on the top and a half oval drawer on the bottom The long edges of the divider will have fingers that will interlock with each half of the oval..

I want to veneer the outside and inside of this oval and will dress the edges with a walnut 1/2" thick edge banding. I am going to acquire some 24" x 96" sheets of walnut veneer. Most have a paper back.

- will this veneer work in wrapping the outside and inside of the oval or will the curvature be too tight and cause the veneer to break. If so what would you recommend that may be a better solution.

- With a glue up like this what would you recommend for glue?

- I do not have a vacuum system or bags I will create a form from MDF to apply the pressure to the inside and outside. I am looking at veneering the insides first while it is still in 2 pieces. Once the 2 halves are together I will veneer the outside.

- Any advice on the gluing of the veneer and thoughts on how to apply the pressure for the glue up.

This will probably be the most ambitious project I will be creating which is going to utilize new techniques and building processes I have never done. This design has been in my head for years and I have put it on paper years ago.

2) I was wondering about your ideal way to glue up book matched door panels. For instance, I have a 4/4 board and I’ll resaw it on the bandsaw. These boards will be my boards to make the panel. The thin boards are usually too thin to put in a clamp. My process is to use blue tape and a friction fit. I’ll put the tape on one side then prop it up in the center and put glue in the joint and wiggle it a tad back and forth along the joint then put more blue tape on the other side. I was wondering if you had another method that would be better.

Thank you for taking time out of your busy lives and sharing your knowledge with the community!

This episode is sponsored by Maverick Abrasives. Check them out at https://www.maverickabrasives.com